Fuel switch support

We retrofit industrial boilers to run on sustainable biomass, helping your business cut emissions, lower costs, and reduce fossil fuel reliance.

Lower fuel costs: Our pellets provide a cost-effective alternative to Heavy Fuel Oil, Heating Oil, LPG, and Paraffin.

Reduced emissions: Lower your carbon footprint and offset carbon taxes.

Proven performance: Efficient operation in step grate & chain grate boilers and specialized pellet burners.

Reliable supply: Locally produced pellets ensure consistent quality and availability.

Why should you

make the switch?

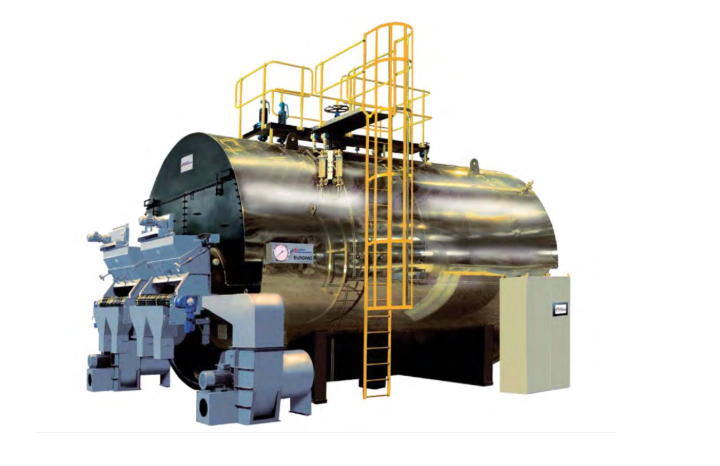

When considering replacement of Gas-fired or Fuel Oil boilers, biomass is an excellent solution to lower both operational expanses and GHG emissions. These boilers do require retrofitting of the burner systems and is a normal practice in many regions around the globe.

Retrofit solutions tailored to your system

We work closely with leading boiler engineering firms to retrofit existing fossil-fueled boilers for biomass use to ensure seamless transitions with minimal downtime.

Full technical feasibility assessment

Engineering and implementation support

Ongoing maintenance and optimization

Potentially funding

Case study - Coal Boiler Test with John Thompson 2025

Biomass is a strong, practical substitute for fossil fuels in steam and heat production. Together with John Thompson, we ran a test program to assess boiler performance and stack emissions when replacing coal with biomass in chain-grate boilers. With no capital investment, the boilers performed nearly on par with coal. With minor modifications and setup adjustments, equal or better performance is achievable.

Results Biomass Fuel vs Conventional Coal burning:

Efficiency: 1% lower NCV efficiency than coal-fired boilers

Emissions: Better than coal

Lower particulate matter

No sulphur dioxide

Very low NOx & TVOC

Ash: 2.5 kg collected per 2-hour test— very low

Combustion & Performance

Stable, even combustion

Highly responsive to loadfluctuations due to

faster gratespeed: 6.25 m/hr (vs 3–4 m/hrfor coal) Turndown Ratio: Same as coal(5:1)